RICHLITE

Richlite is the material from which Epicurean makes its products. Hundreds of food-safe-resin soaked sheets of paper are pressed together under extreme pressure and heat, fusing the individual sheets into a solid piece of material. The final product is exceptionally strong, yet maintains the warm, natural look and feel of wood. It is lightweight, nonporous, knife friendly, and dishwasher safe. It won’t crack, split, or stain—making it a perfect material for cutting boards and earning Epicurean products worldwide recognition.

It also is environmentally friendly. The paper composite raw material comes from Forest Stewardship Council (FSC) certified sources and/or recycled paper. 99.99% of the volatile organic compounds released by the resin are destroyed during the saturation process and never reach the atmosphere. Richlite has earned Greenguard, Rainforest Alliance, and FSC certifications.

We are proud to use this environmentally friendly paper composite, made by Richlite, in the production of our cutting boards and kitchen accessories. The durable material itself has been around for more than 65 years and is widely used for commercial, industrial, and marine purposes, as well as skate park surfaces. It certainly can take anything dished out in the heart of the kitchen.

Paper Roll

Richlite begins as rolls of FSC certified paper which are saturated in resin and trimmed into sheets.

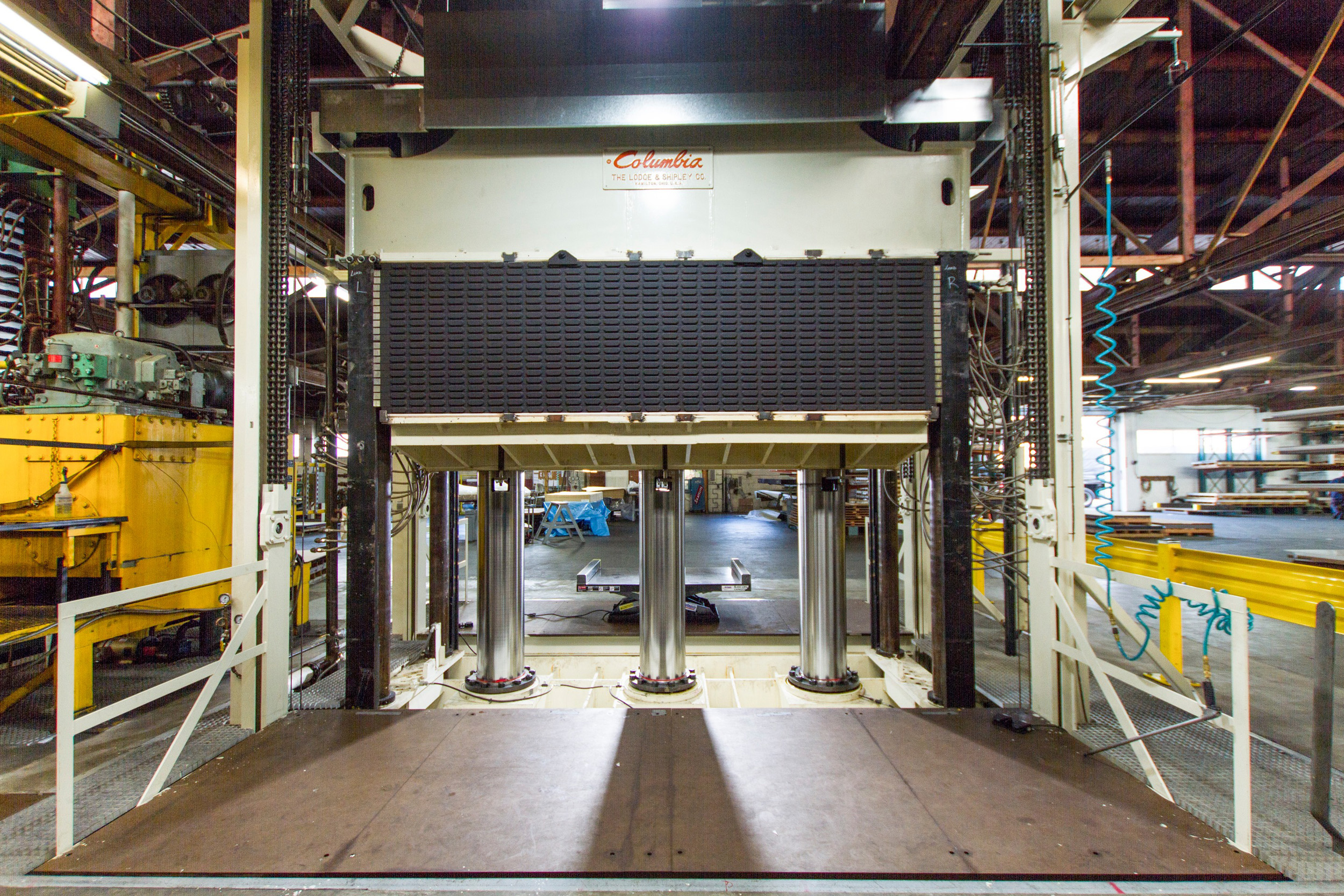

Heat & Pressure

The sheets are stacked to the desired material thickness and pressed with heat and pressure into one solid material.

RICHLITE FEATURES

All Epicurean paper composite products share a set of features that have helped them originate the wood fiber line in both the commercial and housewares industry.

MADE IN THE USA

Richlite is manufactured in Tacoma, Washington from locally-sourced paper pulp. Domestic trucking companies haul the Richlite to Superior, Wisconsin where Epicurean turns it into a wide selection of products.

DISHWASHER SAFE

You’ll save loads of time keeping your Epicurean products clean by simply tossing them in the dishwasher when you’re done using them. Richlite, our signature paper composite material, can be sanitized in any home or commercial dishwasher.

HEAT RESISTANT

Our paper composite material is heat resistant. You can keep your counters safe from hot pots and pans by using your boards as trivets, and your Epicurean tools will stand up to the high heat of sautéing and boiling. This material should not be used as cookware, however.

EASY ON KNIVES

Epicurean paper composite boards are harder than wood but will score slightly while slicing and chopping food. Your knives will stay sharp longer, making your prep work faster and easier.

FROM SHEET TO CUTTING BOARD

The first step in crafting a new Epicurean product is sparking an idea. Fortunately, our staff never run dry of ideas. Once the ideas are narrowed, our product designer and programmers get to work sketching, prototyping, and refining that idea into a tangible piece. The material of desired thickness and color is ordered and shipped from Tacoma, Washington. Stacks of sheets are staged at our CNC machines, the cut program is entered, and the operators work their magic. In minutes a single sheet is transformed into dozens of products, ready for laser engraving, labeling, boxing and shipping.

Warehouse to Machine

Full sheets move from the warehouse to the machine floor to be cut into product parts on a CNC machine.

Lasered & Labeled

After the parts are machined, they are put into the laser machine to have the Epicurean brand etched into the surface. From there they are labeled and boxed for inventory.

Other Uses

Richlite is used in a variety of industries to fabricate everything from cladding on large buildings to small fret boards on guitars.

Skate Park Surfacing

The entire riding surface is covered in the same material used to make Epicurean cutting boards. Thats one really big cut cutting board..

Furniture & Architecture

This durable material is so diverse, you'll see it used to side architectural buildings and fabricate furniture.